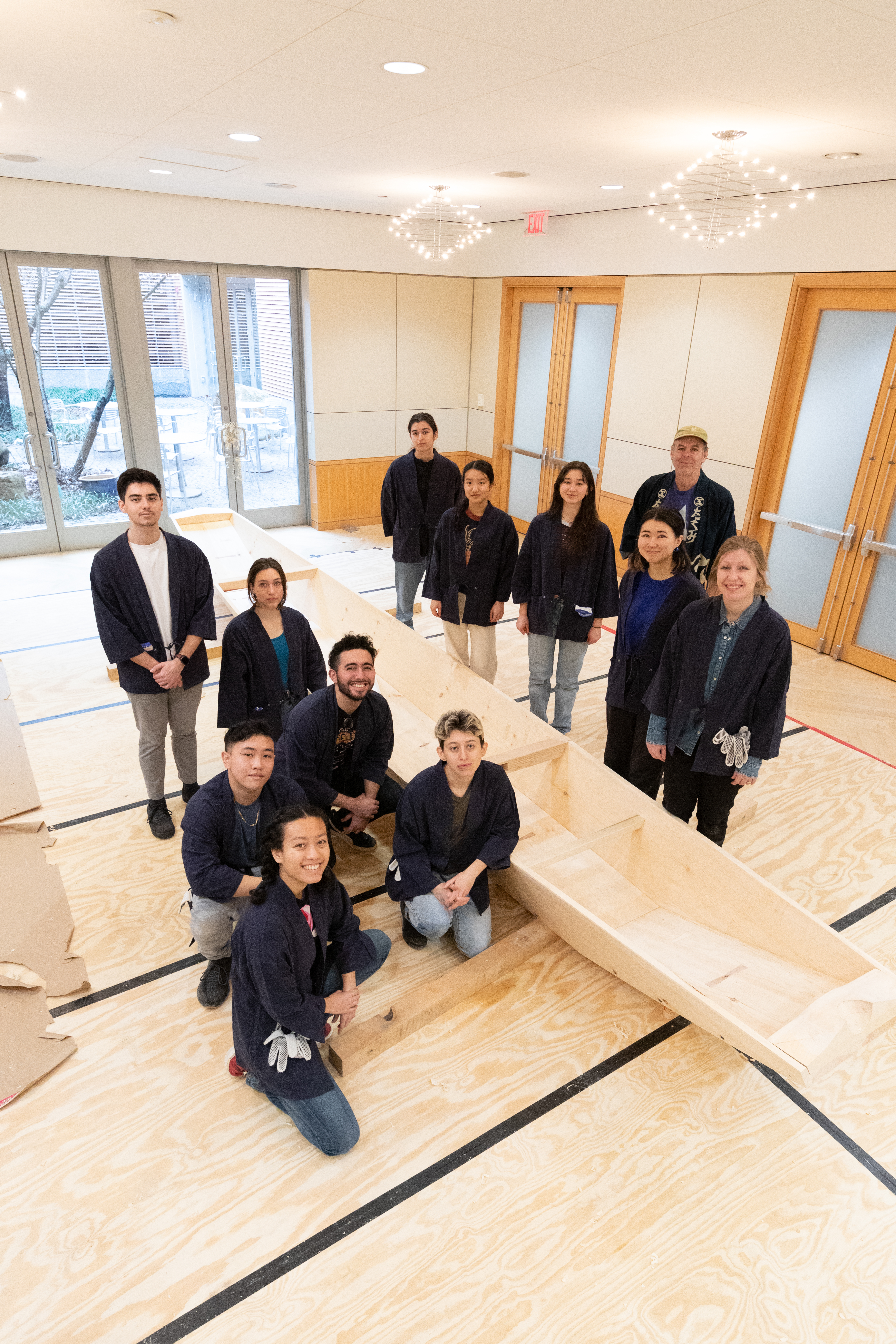

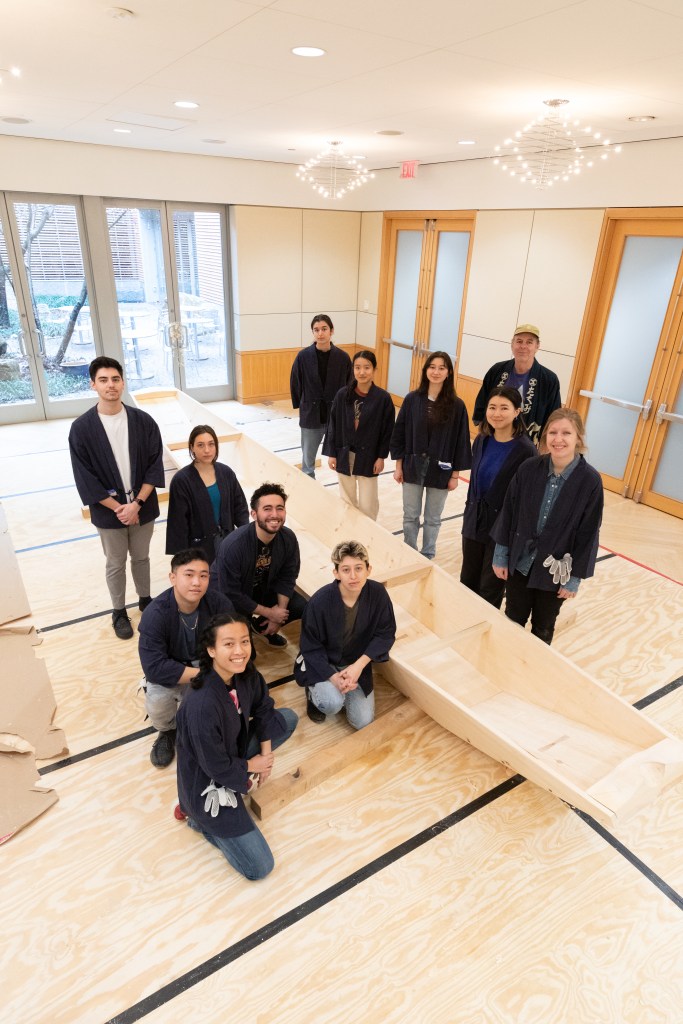

This was a winter session program organized by Harvard’s Reischauer Institute for their 50th anniversary. The Reischauer Institute supports research on Japan and helps facilitate many exchange programs in Japan as well.

The workshop was led by Douglas Brooks, a boatbuilder who traveled all over Japan apprenticing to many master boatbuilders and recording their work process as part of a preservation process.

The focus of the workshop was the construction of a 21-foot honryōsen, a working skiff native to Niigata Prefecture’s Shinano River basin. Using traditional tools and techniques taught in an apprenticeship-inspired learning environment, participants gained a deeper insight into the materials, customs, and relationships that shape the art and craft of Japanese wooden boatbuilding today. At the end of the workshop, participants physically moved the honryōsen from the workshop into CGIS’s Friends of Japan Concourse area. There it played a central part in a Reischauer Institute-organized exhibition that ran through the end of March. Titled In the Making: Learning from Japanese Wooden Boatbuilding, the exhibition highlighted the history and culture of Japanese wooden boatbuilding while inviting the audience to explore—from multiple vantage points—the dimensions of embodied learning and discovery inherent to the making process itself.

The workshop gave me an opportunity to build something with my own hands, with people from all kinds of different areas of study. They were truly one of the best things about the experience!

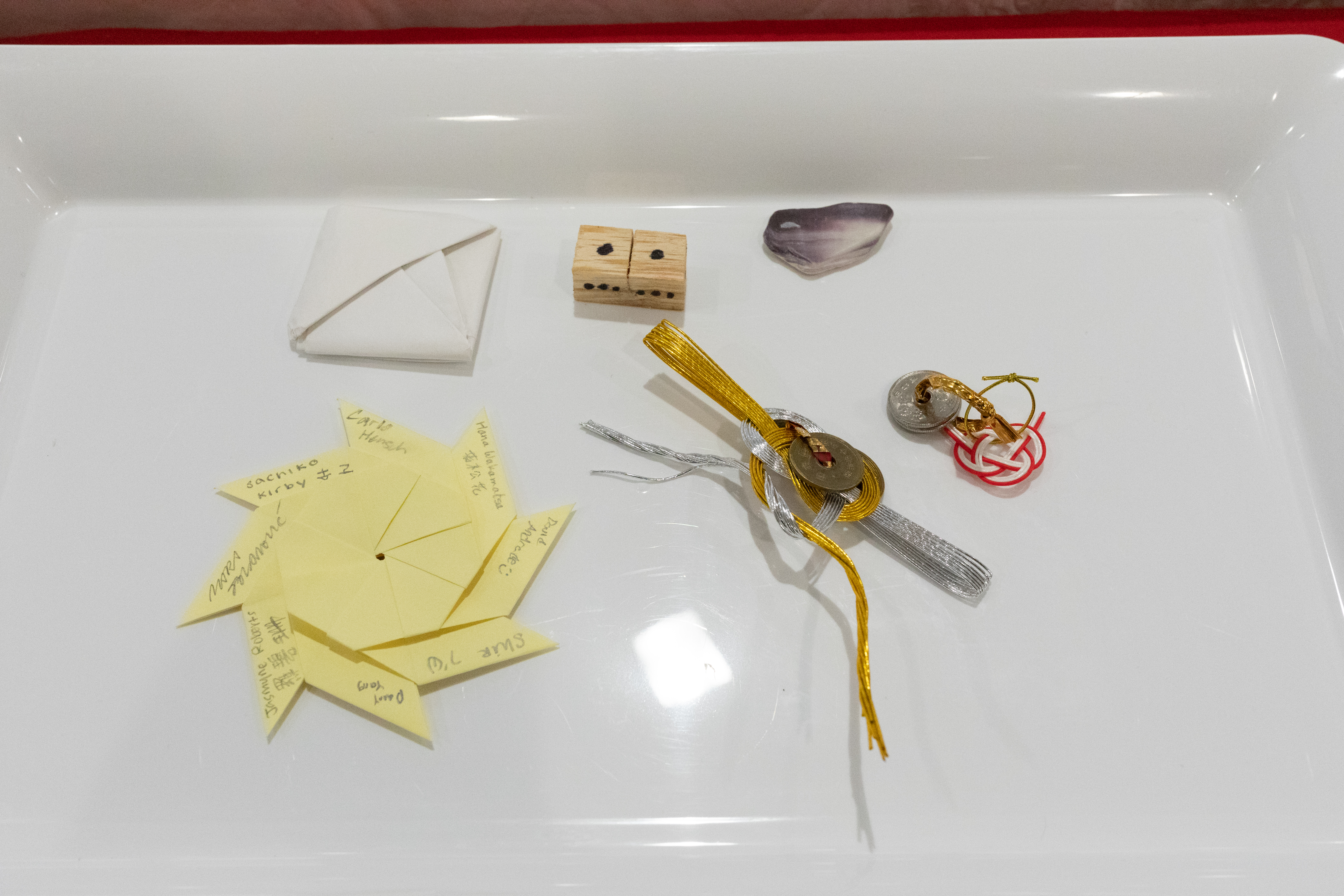

As part of the experience, we took a traditional approach to as much of the construction as possible. This meant doing traditional ceremonies at the point when we had finished the floor of the boat as well as when we finished the whole thing.

The series of object laid out in the upper right image to the right are objects that were placed in a sealed, watertight compartment in the boat. It will never be opened again, and is a traditional practice in Japanese boatbuilding.

Below are some of the tools we used in constructing the boat. Many of them look and function similar to the Western version of the tools – such as the handsaws, chisels, planars, and hammers – but they have subtle differences. The planars are used by pushing them away from your own body, and they are extremely light compared to western style planars.

The chisels are also made out of a harder steel than wester chisels – it takes more work to get a perfect point, but they last longer. The teeth in the saws differ from western style saws because instead of being flat and meant for only a back and forth motion, they are actually bent slightly outwards. This is to help with the ‘rubbing’ process in fitting boards together – by scraping parallel with the seam of the wood, you create a watertight seal.

There were a couple of students belonging to Harvard’s School of Engineering and Applied Sciences department doing the workshop, and the department wrote a short article on the workshop.