< Return to Engineering Projects

This project was created in May 2022.

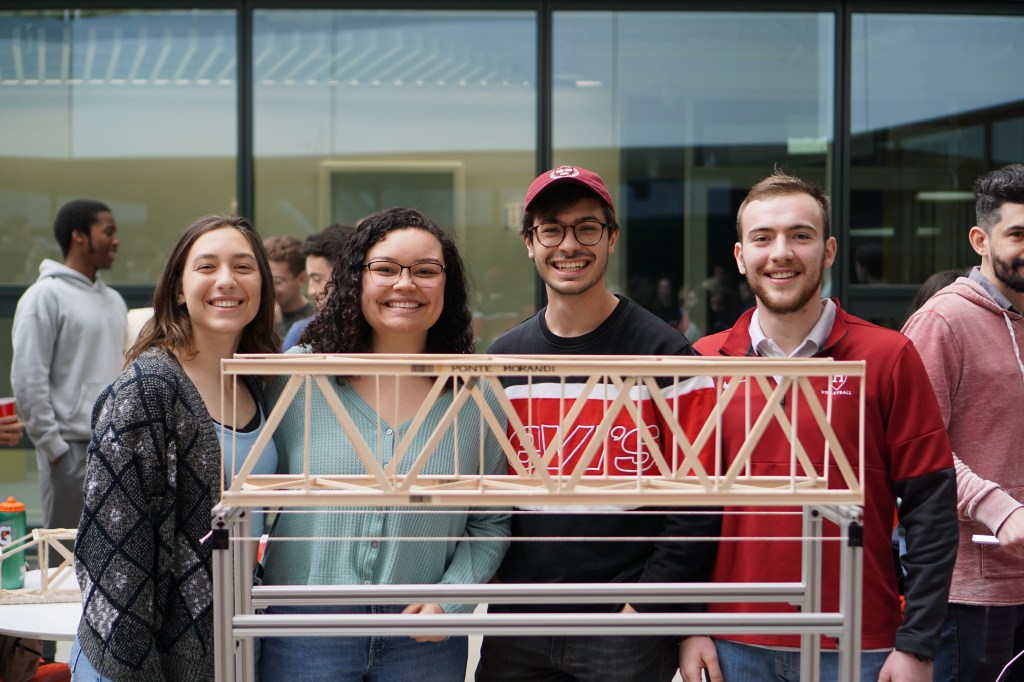

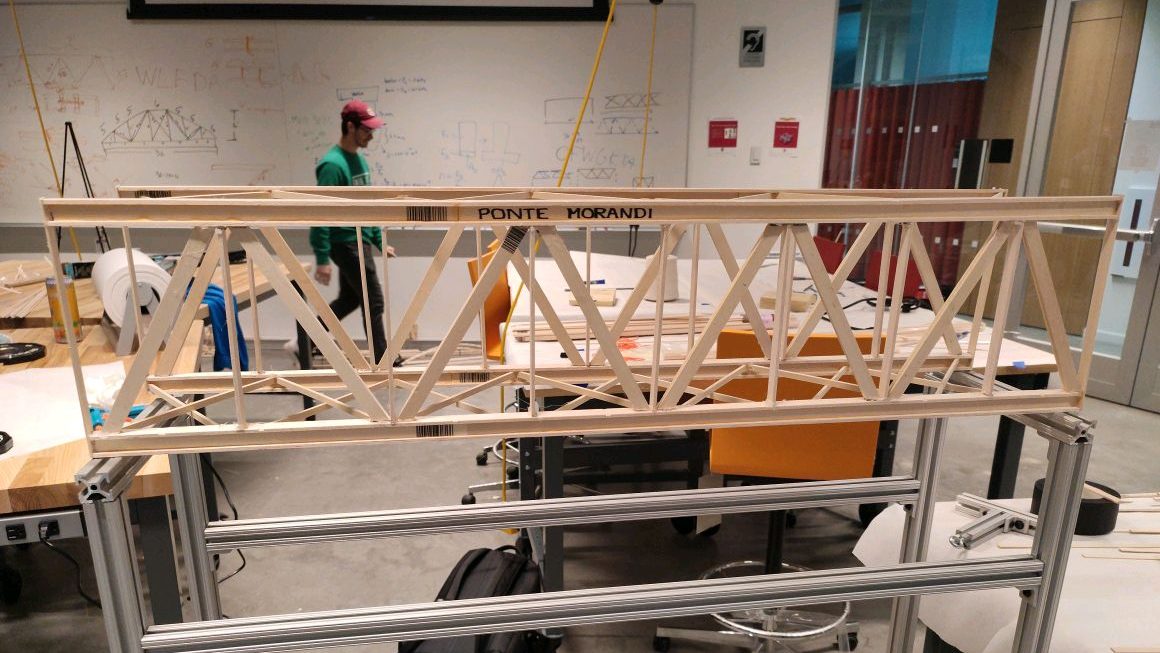

Project partners were Mia Wright, Tomasso Serafin, and Alessio Pignatelli.

Our bridge was built as a final project for our engineering class, ES 120: Introduction to the Mechanics of Solids. The assignment was to design and build a bridge that would be able to withstand a certain minimum load, with minimum deflection. The project was presented at a ‘Bridge Party’ at the end of a semester, and we were given roughly two to three weeks to work on it.

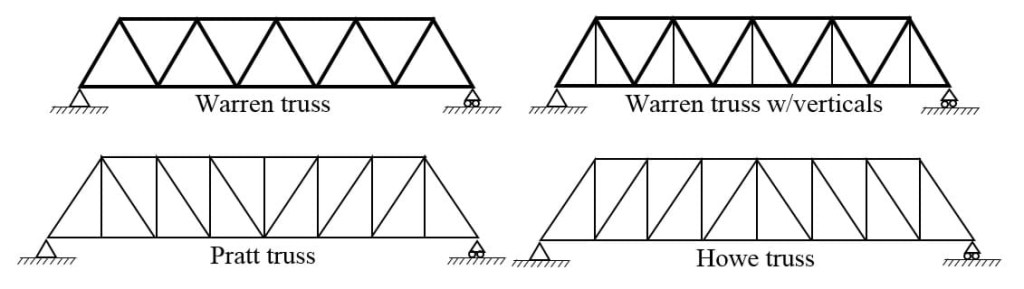

Our group knew from derivations we had done in class that a simple truss bridge would be the best thing to make – trusses distribute stress along the beams so that point loads are reduced.

Other kinds of bridges might in theory have been more sturdy, but we also thought we should account for our construction expertise and the time limit.

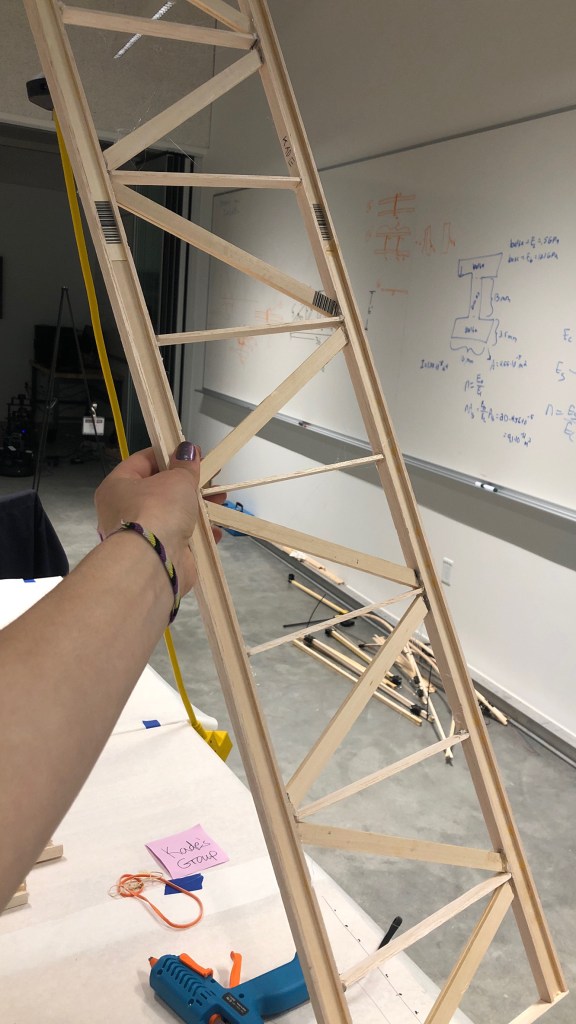

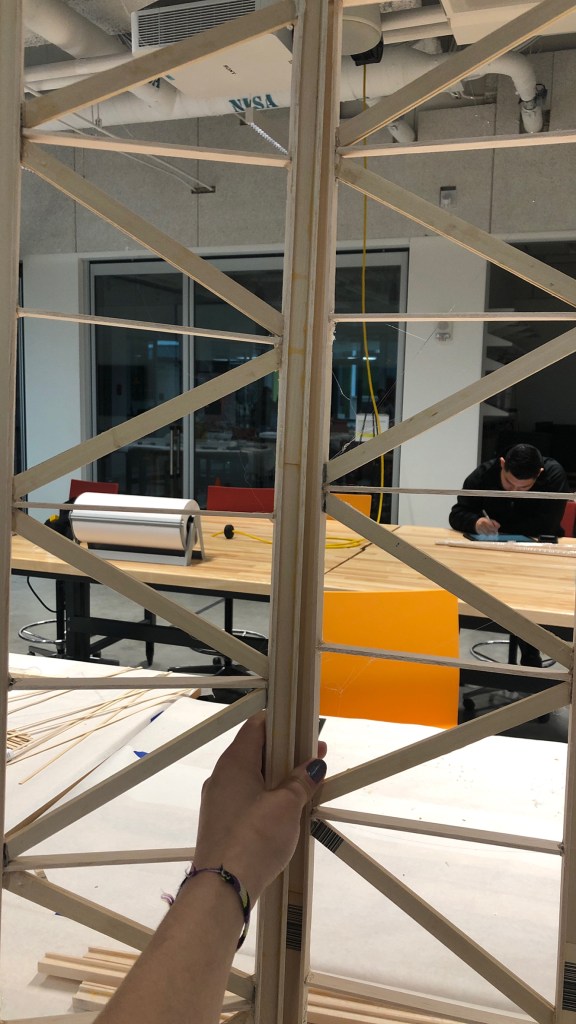

We built two side panels with vertical supports and trusses. The vertical supports are made with very thin balsa wood, since we anticipated them not experiencing much stress. The slanted pieces of the truss are made with thicker and more firm pieces of wood, as these are the force redistributors. The horizontal supports are I-beams made using both balsa wood and the firm birch wood provided. The birch wood is the center support of the I-beam, as the load will be applied to the shorter side and this will decrease deflection. The balsa wood was chosen for the outer pieces of the I-beams in order to reduce weight.

The Bridge Party!

Our bridge did not fail! There was also hardly any deflection. Until we decided to REALLY test the limits and had someone press their full body weight onto the bucket of water that was the functioning point load for the bridge. Even then, there remained no vertical deflection along the bottom and our side trusses remained intact. The failure pattern told us that with some simple modifications our bridge could be even more sturdy.